Everything You Wanted to Know About Vodka, but didn’t Know How to Ask

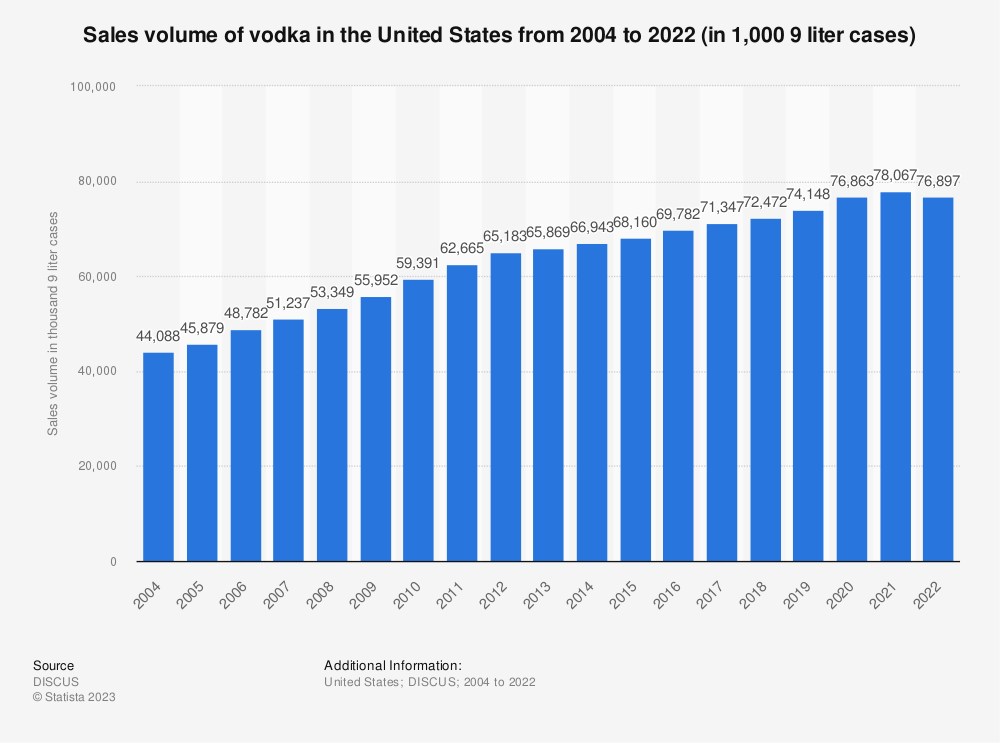

Vodka is the world’s most popular spirit with retail sales in 2022 estimated to be in excess of $41 Billion, with over half of that figure generated in the United States alone. Vodka sales in the U.S account for 31% of all spirits sales; a whopping 77 Million cases per year! Yet, many consumers don’t really know how vodka is made or how to evaluate quality.

With the popularity of vodka, there are still a lot of open questions about this spirit with regard to quality, price and value. Are all vodkas the same? What makes one vodka worth more than others? What makes a vodka “premium?”

Regulation of label information of spirits in the U.S. restricts many distillers from disclosing a lot of information for various reasons. The U.S. Government has strict guidelines for the number of claims a distiller can make in an effort to set uniform standards and protect the consumer. However, the current labelling system for vodka (and spirits in general) does not provide much depth for objectively evaluating quality of the contents.

It’s no secret that off-label information contained in advertisements, store promotions and sponsorships do more to drive perception of vodka value than anything else. Large corporate distilleries have massive marketing and advertising budgets to influence the perception of their products. So, in that sense, spirits are like any other consumer product, the more you know, the better you are able to cut through the noise of corporate propaganda.

We’ll attempt to unpack some of the myths and facts about vodka.

What is vodka?

Vodka, as defined by U.S. law, is diluted ethyl alcohol or Ethanol. To be designated as vodka, the liquid must contain a minimum of 40% (ethyl alcohol) by volume. The rest is essentially water. Vodka can be made from virtually any product that can be fermented and distilled to produce high-proof alcohol. A little bit more about the process of how vodka is made; the law in the US states that the ethyl alcohol volume must reach a purity of approximately 190 proof (95% alcohol by volume “ABV”), which is then diluted (or proofed) down to a minimum of 40% ABV.

Origins

The exact origins of vodka are not exactly known and there are differing accounts of where and how it emerged as a libation. However, it is generally agreed that vodka originated somewhere in Eastern Europe or Russia. Again, exactly where is a matter of debate.

It is also a topic of debate whether vodka was first made using potatoes or cereal grains (wheat, barley, sorghum). Although, potatoes would have been difficult to grow in any commercial quality in many areas of Russia because of the cold climates most of the year as well as the lingering ground frost.

The more popular brands of American vodka are predominantly corn-based. However, there is an emerging trend of using sugarcane juice to produce a cleaner, smoother form of ethyl alcohol and of course, vodka.

Each of the base agricultural products mentioned above will yield a unique vodka, with varying levels of smoothness, smell and “mouth-feel.” In addition, each of these agricultural products require differing processes and additives to make vodka.

How is vodka made?

What is vodka made from? Vodka, like any alcoholic beverage is made by fermenting sugar (glucose) by the addition of yeast. Keep in mind that traditional products used to make vodka like wheat and potatoes are high in starch and do not have enough freely available fermentable sugar on their own to make alcohol, so they must undergo some additional treatment and additives to reach and expose desirable (fermentable) sugar levels. While glucose is a main component of starch, it is intricately bound on a molecular level within grains and potatoes and must be isolated by the addition of enzymes.

As we will discuss, this additional treatment and the addition of enzymes (alpha and beta amylase) also results in the creation of multiple chemical by-products. Unfortunately, these by-products can be toxic and have harsh flavor characteristics. This is where cereal grains and potato-based vodka differ vastly from sugar-based vodkas like sugarcane vodka or grape-based vodka.

Creating a Mash (required for grains, potatoes or corn)

When using potatoes, corn, wheat or other grains, the distiller must first prepare the base product by milling or emulsifying the raw materials in water. This stage is known as the mash phase. Mashing is the physical breakdown of the plants in preparation for further chemical breakdown using enzymes. The (“mashed”) contents will likely have a thick, soupy consistency (approaching thixotropy) with the presence of solids and starch granules.

The mash is then heated to help break down the starches and allow water to saturate the starches to achieve a gelatin-like (thixotropic) state which indicates that the water has penetrated the starch molecules, basically exposing the glucose-containing molecules. At temperatures of approximately 150-160 degrees F the distiller will add enzymes to essentially finish the process of isolating the glucose molecules. The enzymes act to separate the molecular structure of the starch from the glucose molecules.

At this point the liquid become thinner as the composition of the mass is broken down and is curated to allow the yeast to consume the sugar. When yeast metabolizes sugar, it creates alcohol. This is where vodka manifests its different profiles. As we will soon show, adding enzymes produces several other chemicals and compounds.

Creating a Wash

Prior to adding the yeast, the mash is strained to remove any solids. What the distiller wants (and needs to ferment) will be fully diluted in the water.

Fermentation

When yeast is combined with the wash (referred to as “pitching the yeast”) in an air-tight container (anaerobic fermentation), yeast “feeds” on the sugar to produce mainly ethyl alcohol and CO2.

However, depending on how the mash was created and what ingredients were used (starches/enzymes), the yield of the fermentation will likely contain impurities that will influence flavor or smoothness perception. Some of these impurities are: methanol, acetaldehyde, isoamyl alcohol, propanol and fuseoils. Most of these impurities will be removed during distillation, but the volume of trace amounts remaining separates premium vodka from cheap vodka. The difference can be quite significant.

Fermenting with Sugarcane Juice is a Natural and Cleaner Process

Sugarcane (or sugar cane) juice contains ample quantities of freely available, fermentable sugar without the need for mashing or the addition of enzymes to avail the glucose needed for fermentation. It therefore can be fermented naturally and much cleaner than grain or potato-based washes. That is why sugarcane vodka will be smoother and have a more pleasant aroma.

The tolerance of distilling yeast to alcohol content can vary slightly but is bound by a threshold of approximately 19%-20% alcohol by volume. Yeast is actually a living organism and cannot survive in an environment of more than 20% alcohol. So, in most cases, after about 10-14 days of fermentation, yeast will literally choke itself to its end by producing alcohol.

Distillation

So, after the yeast colony expires and the wash reaches its maximum alcohol content, it’s time to isolate the ethyl alcohol from the other components in the wash (water, methyl, etc.). This is achieved by the process of distillation. Distillation allows the distiller to separate and collect different chemicals produced during fermentation according to their boiling (or vapor) points.

The distiller’s fermented wash is strained once again to remove any remaining solids and the lees or “trub” (layer of slimy sediment composed of spent yeast) that falls to the bottom of the fermentation vats. The fermented liquid is then poured into a boiler of a pot still or column still.

Distillation is a process of vaporizing, condensing and capturing the components of the fermented wash at different temperatures. At lower temperatures, most of the undesirable compounds of the wash will remain in vapor form, while the ethanol (pure vodka) will condense and fall back into the boiler (see reflux action below). The undesirable compounds are allowed to pass as vapor to a second segment of the column where they are cooled and condensed into liquid form and collected.

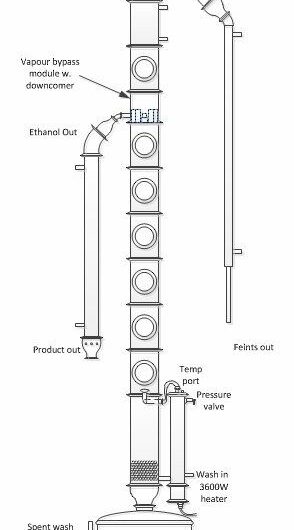

Column Stills and the Use of copper in distilling

Column stills are made from stainless steel and comprises a tall column structure attached above the top of the boiling kettle designed to attain purer vapors. The column portion is divided into chambers using perforated (copper) plates. The still is constantly heated at the bottom, so when the fermented wash is poured from the cooler top part and it hits the steam, it vaporizes and sends the alcohol back to the top.

In the case of a reflux column still, the vapors rise through the tubular stainless steel or copper column segments separated by the perforated copper plates and the properties of the copper remove volatile Sulphur compounds released by the yeast during fermentation. This process repeats at lower temperatures as the ethanol vapors rise, condense and fall back down the column (reflux action). As the ethanol rises through the vapor path and falls as condensed liquid over the copper, sulphur is removed.

Distillation consists of four stages:

- Foreshots – These are the first chemicals to vaporize and contain highly toxic materials such as methanol. Methanol is a neuro-toxin and can be very hazardous even in low concentrations. This process occurs at temperatures of 175°F.

- Heads – The next phase of distillation are Heads and this takes place at temperatures between 175°F to 185°F. The heads can contain trace amounts of substances that can significantly affect the flavor of the spirit.

- Hearts – As the name implies, this is the good stuff. This is the liquid rich in high-proof ethanol that makes quality vodka. This occurs at temperatures between 190°F and 205°F. This stage must be monitored closely and cut before the next stage begins.

- Tails – Are similar to the Heads in that they will contain some unpleasant flavors; and will start to drop in concentration of ethanol as water (which boils at 212°F) will start to dilute the hearts in undesirable ways.

Number of Times Distilled?

The “number of times distilled” designation on many vodka bottles has become more of a marketing gimmick rather than an indication of production integrity or quality. Technically, a distillation count is equivalent to the number of chambers in the column portion of the still. In the image below, this would be 7x distilled (each circle represents one distilling chamber).

This may have been relevant in times of backwoods moonshiners, where the distilling equipment was crudely fabricated, usually homemade and measurement of compounds was relegated to taste and discretion of the moonshiner. Today’s advanced distilling equipment can measure precise yield output and detect the presence of all substances in the liquid. Distilling has evolved to a science that is highly precise and efficient.

In most cases, properly fermented vodka will require only 4 times distillation. Beyond that, there is no meaningful, discernable or measurable benefit to additional distillations, let alone 51 times distilled, as some vodka-makers declare. One of the world’s most famous premium vodkas, Grey Goose, is distilled only one time.

Think of the early days of home audio equipment when manufacturers sold massive speakers and touted their size as a determination of music quality. Or, think of razor-blades; two blades, three blades or now five blades! We now know that one blade works just as well. That was a way to sell a product that had no additional benefit for a higher price…It’s very much like that.

Based on what we have just reviewed, a high-quality vodka would not need to be distilled over and over. If your vodka needed 51 distillations, you likely had an impure fermentation. We firmly stand behind the notion that number of times distilled is relatively meaningless and should be disregarded as a measure of quality or taste.

FACT: Vodka made from sugarcane, grapes or other natural sugar source does not produce most impurities found in potato, corn or wheat vodkas…so it starts-out cleaner.

Proofing

Once the hearts of the distilling run are collected, they are approximately 95% ethanol by volume (190 proof). To be called vodka in the U.S. the alcohol by volume must be a minimum of 40% (80 proof), so the ethanol needs to be “proofed-down” to 40% alcohol by volume (ABV) or 80 proof. This is done simply by adding water to the high-proof ethanol. Well, maybe not so simple.

Technically, proofing is actually the process of creating a hydrate of water and ethanol. Despite the intricacies and science of what preceded this point, proofing arguably can have the most profound impact on the perception of flavor or smoothness. This is attributed to water quality and in some cases the pH of the water.

In the process of proofing (hydrate) we are adding almost 2.5 times the water volume to the ethanol to achieve 40% ABV. So, it stands to reason that water would have a profound impact on your vodka. When high proof alcohol is added to water, the water molecules create a molecular chain around the ethanol molecules…it is the first thing you taste when sipping vodka.

For this reason, many drinkers will have differing taste perceptions when it comes to vodka. This has a lot to do with how the hydrate is formed and the consumer’s physical reaction to it or their perception of flavor and smoothness.

As we have demonstrated here, not all vodka is the same quality, but in the end, it really is a matter of taste. However, the overwhelming majority of consumers will say that the effects of cheaper/lower-quality alcohol are very apparent on digestive well-being or the “hang-over” effects the day after.

Filtration

We’re not done yet. Vodka’s journey to the perfect martini requires a final filtration. Carbon filtering is an industry standard. However, the technique varies depending on the quality standards of the distiller. Carbon filters use active charcoal which creates chemical bonds to impurities and dissolved solids to filter the proofed vodka. This also provides and additional finishing smoothness to vodka.

Oddly, many distillers opt for a low-tech, low-cost approach to filtration; and after all that needs to be done to get to this point, it seems neglectful to simply go through the motions of low-end granular carbon filtration.

Most vodka distillers will pack a stainless-steel pipe with granular, activated charcoal, then pour their proofed vodka into the top and let it pass through the charcoal, powered by gravity and a screen or fine mesh at the bottom. This is very much identical to how a common home water filter works.

Premium distillers like Felene use solid a carbon block and push their proofed vodka through the solid carbon at low pressure, ensuring the proofed vodka has deep contact with the carbon. It’s a time-consuming and expensive process, but the results are undeniable. In the case of Felene, after carbon filtration, the vodka is filtered again using a .65 micron, poly-pleated filter, almost 8 times as fine as the industry standard of 5 microns.

A note about Additives and Reverse Osmosis

While it seems counter-intuitive, U.S. vodka distillers are permitted to add up to 0.01% concentration of citric acid and up to 0.02% concentration of sweeter to their vodka and still claim it contains no additives. FELENE ACTUALLY CONTAINS ZERO ADDITIVES. We do not have any additives in our vodka.

It is estimated that 90% of commercially available vodka in the U.S. use citric acid and sweeteners to make their vodka present smoother by masking harsh flavors and the burn associated with most vodkas. This includes most of the leading-selling domestic and imported vodkas.

Why does that matter? For starters its just not genuine and the only reason to do it is to mask an inferior product. Additionally, the important part of “citric acid” is “ACID!” Citric acid lowers the pH of vodka and makes it acidic. This is usually associated with lower-priced, lower-quality vodka. Well-made vodka does not require balancing agents and sweeteners, so they maintain naturally higher pH levels.

Felene Vodka is just naturally a better-tasting vodka. It is also naturally gluten-free, organic and nonGMO.

What Determines the Price of a Bottle of Vodka?

In the case of “premium” vodkas, the biggest expense in producing the finished product is often the glass bottle itself. In the case of the more popular premium vodkas, the glass bottle costs as much or more than the vodka inside. A fancy bottle means a higher cost to you, not always a better vodka.

If you are buying a bottle of vodka to decorate your bar with elaborate glass shapes and designs, then beauty (and value) is in the eye of the beholder. But if you are looking for superior quality of the liquid, bottle design is just an added expense, and can account for 1/3 the cost of the product.

All too often, a vodka brand is considered premium because of its price, not because of its contents. An educated consumer should disregard packaging. And just as often, how a brand is marketed can influence perception of quality in the mind of the consumer. As discussed previously, meaningless claims of “number of times distilled” and elaborate packaging are used to inaccurately validate quality. Make no mistake, these things speak less about quality and speak to marketing budgets of the brands.

You must be logged in to post a comment.